Carport assembly is a straightforward process that can be completed with basic DIY skills․ Most kits include step-by-step instructions and all necessary materials for a successful project․

1․1 Importance of Proper Assembly

Proper assembly of your carport is crucial for safety‚ stability‚ and durability; A well-assembled structure ensures it can withstand weather conditions and protect your vehicles effectively․ Improper installation may lead to structural issues‚ such as uneven roofing or weakened frames‚ which can compromise safety and longevity․ Following the instructions carefully prevents costly repairs and maintains the integrity of the carport․ Regular maintenance‚ like painting and anti-rust treatments‚ also becomes easier when the assembly is done correctly․ A properly assembled carport not only provides reliable shelter but also enhances the aesthetic appeal of your property‚ ensuring it remains a valuable asset for years․

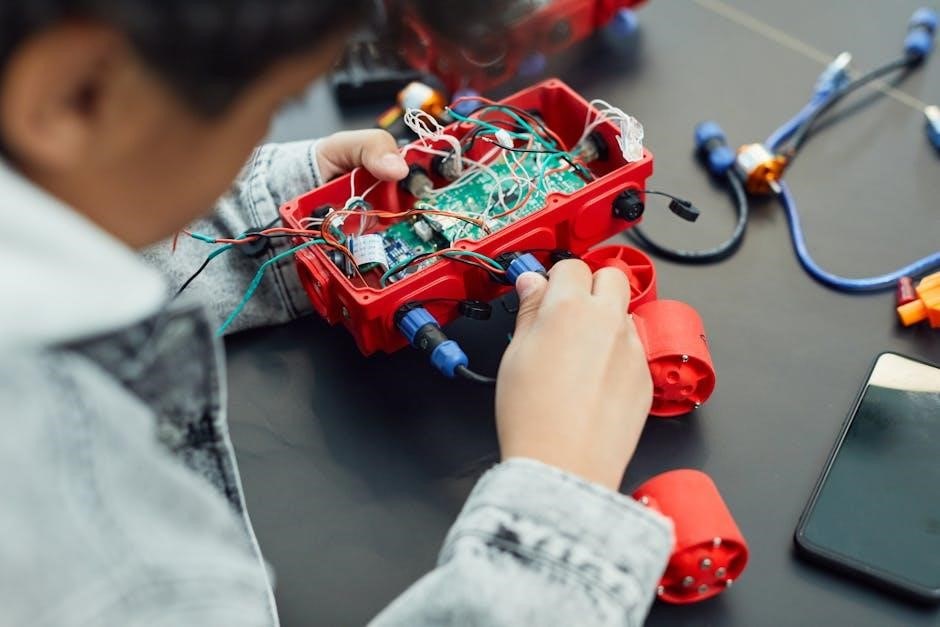

1․2 Benefits of DIY Carport Assembly

DIY carport assembly offers several advantages‚ including cost savings and the satisfaction of completing a project independently․ Many carport kits are designed for easy assembly‚ requiring only basic tools and skills․ This approach allows homeowners to customize the structure to fit their specific needs and preferences․ Additionally‚ assembling the carport yourself ensures that you understand its construction‚ making future maintenance and repairs more manageable․ The process typically takes a few days‚ depending on the size and complexity‚ making it a feasible weekend project․ With clear instructions provided‚ even those new to DIY projects can achieve professional-quality results‚ enhancing their property’s functionality and appearance․

Preparation and Planning

Preparation and planning are crucial for a smooth carport assembly․ Ensure site selection‚ measure accurately‚ and gather all necessary tools and materials before starting the project․

2․1 Tools and Materials Needed

Assembling a carport requires specific tools and materials to ensure a successful project․ Essential tools include a drill‚ wrench‚ screwdriver‚ measuring tape‚ and level․ Materials like concrete for the foundation‚ posts‚ beams‚ and roofing panels are also necessary․ Additionally‚ make sure to have safety gear such as gloves and goggles․ A complete inventory of parts and step-by-step instructions are typically provided with DIY carport kits․ Double-checking the kit’s contents and preparing all tools in advance will streamline the assembly process and help avoid delays․ Proper organization of materials and tools is key to a stress-free DIY experience․

2․2 Site Selection and Measurement

Choosing the right location for your carport is crucial for both functionality and aesthetics․ Ensure the area is level and clear of obstructions․ Measure the space to confirm it aligns with your carport’s dimensions․ Check local building codes and regulations to avoid permit issues․ Stake out the perimeter using stakes and string to visualize the structure’s placement․ Ensure the site is accessible and well-drained to prevent water accumulation․ Accurate measurements are essential to maintain stability and ensure proper fit of all components․ A well-selected and prepared site lays the groundwork for a successful and stress-free assembly process․

2․3 Understanding the Assembly Manual

Before starting‚ thoroughly review the assembly manual provided with your carport kit․ Familiarize yourself with the contents‚ including diagrams‚ step-by-step instructions‚ and safety precautions․ Check the inventory list to ensure all components are present and accounted for․ Pay attention to specific tools required and any technical terms used․ The manual serves as your guide‚ so understanding it fully will streamline the assembly process․ If unclear‚ refer to online resources or contact customer support for clarification․ A clear understanding of the manual ensures a smooth and error-free installation‚ helping you achieve a sturdy and durable carport structure․

Step-by-Step Assembly Guide

Begin with site preparation‚ leveling the ground‚ and laying the foundation․ Assemble the frame‚ install roof support beams‚ and secure roofing panels․ Complete with final checks for stability and safety․

3․1 Preparing the Site

Preparing the site is the first critical step in carport assembly․ Clear the area of debris‚ vegetation‚ and obstructions․ Measure and mark the perimeter using stakes and string to ensure accurate dimensions․ Check the ground for levelness and excavate if necessary to create a stable base․ Use a shovel or digger to prepare the earth‚ ensuring it is firm and even․ Refer to the assembly manual for specific measurements and layout instructions․ Proper site preparation ensures the carport is erected safely and securely‚ preventing structural issues later․ This step requires patience and precision to lay a solid foundation for the project․

3․2 Laying the Foundation

Laying the foundation is essential for a stable carport structure․ Begin by digging holes for the posts‚ ensuring they are deep enough to anchor the carport securely․ Pour concrete into each hole‚ following the instructions provided in your kit․ Carefully lower the posts into the concrete‚ making sure they are vertically aligned using a spirit level․ Allow the concrete to set completely before proceeding․ Once set‚ the posts will form the base of your carport․ Properly laid foundations ensure the structure remains durable and resistant to environmental factors like wind and rain․ Always refer to your assembly manual for specific depth and spacing requirements․

3․3 Assembling the Frame

Assembling the frame is a critical step in your carport project․ Begin by attaching the crossbeams to the posts‚ ensuring they are securely fastened using the provided connectors․ Follow the instructions to connect the side rails and roof supports‚ forming the skeleton of your carport․ Use a wrench to tighten all bolts firmly‚ but avoid overtightening to prevent damage․ Double-check that the frame is square and level before proceeding․ This step requires patience and attention to detail to ensure the structure is stable and properly aligned․ Once the frame is complete‚ it will serve as the backbone for your carport‚ supporting the roof and providing durability․

3․4 Installing Roof Support Beams

Installing roof support beams is essential for ensuring the structural integrity of your carport․ Begin by placing the beams across the top of the frame‚ aligning them with the pre-drilled holes․ Secure the beams using the provided brackets and bolts‚ tightening them firmly with a wrench․ Ensure the beams are evenly spaced and level to distribute weight evenly․ For added stability‚ attach crossbeams between the main support beams․ Double-check the alignment and tighten all connections to prevent shifting․ This step ensures the roof can withstand external forces like wind and snow․ Refer to the manual for specific beam placement and securing instructions․

3․5 Adding Roofing Panels

After securing the support beams‚ begin installing the roofing panels․ Start by placing the first panel along one edge‚ ensuring it aligns with the frame․ Use the provided screws to fasten the panel to the beams‚ spacing them evenly for a secure fit․ Repeat this process for each subsequent panel‚ overlapping them slightly to ensure waterproofing․ For metal panels‚ use a rubber mallet to avoid scratching; Once all panels are in place‚ check for gaps and ensure tight connections․ Finally‚ install any ridge caps or trim to seal the roof edges‚ completing the carport’s protective cover․

3․6 Final Checks and Adjustments

Once the carport is fully assembled‚ perform a final inspection to ensure all components are secure and properly aligned․ Check that the roof panels are tightly fastened and evenly spaced‚ with no gaps or loose screws․ Verify that the frame is level and stable‚ making any necessary adjustments to the foundation or supports․ Ensure all bolts and brackets are tightened firmly to withstand weather conditions․ Finally‚ inspect the entire structure for any missing or damaged parts and address them immediately․ This thorough check ensures your carport is safe‚ durable‚ and ready for use‚ completing your DIY project successfully․

Design and Customization Options

Carports come in various sizes‚ roof styles‚ and materials‚ allowing customization to suit your needs․ Popular sizes include 12‚ 16‚ and 20 feet wide․ Choose from flat‚ gabled‚ or slanted roofs for aesthetic appeal․ Metal and wooden options offer durability and style‚ while additional features like lighting or storage can enhance functionality․ Customize colors and designs to match your home’s exterior for a seamless look‚ ensuring your carport is both functional and visually appealing․

4․1 Popular Carport Sizes

Popular carport sizes range from 12 to 25 feet in width‚ accommodating single vehicles‚ RVs‚ or boats․ A 12-foot-wide carport is ideal for compact cars‚ while 16-foot models suit larger vehicles․ For extra space‚ 20-foot carports are versatile‚ and 25-foot options cater to multiple cars or equipment․ Each size ensures efficient use of space while protecting vehicles from weather conditions․ The choice depends on the number of vehicles‚ available yard space‚ and personal preferences․ These standard sizes are cost-effective and durable‚ making them suitable for both residential and commercial needs․ Selecting the right size ensures optimal functionality and value for your investment․

4․2 Roof Styles and Designs

Carport roof styles vary to suit different preferences and needs․ Flat roofs are DIY-friendly and offer a modern look‚ while gabled roofs provide excellent weather protection․ Some designs‚ like the Vitoria 5000‚ feature upscale aesthetics for a versatile structure․ Metal carports often come with color options to match your home’s style․ Regular maintenance‚ such as replacing coverings and applying anti-rust treatments‚ ensures longevity․ Whether you prefer a sleek‚ functional design or a decorative option‚ carport roofs can be customized to complement your property’s appearance while providing durable protection from the elements․ Choose a style that balances practicality with visual appeal for your space․

4․3 Material Choices for Durability

Choosing the right materials is crucial for a durable carport․ Metal carports‚ especially those made from double-galvanized steel‚ offer excellent strength and resistance to rust and corrosion․ Wooden carports provide a traditional aesthetic but require regular maintenance‚ such as painting and anti-rust treatments‚ to withstand weather conditions․ Some kits feature pre-engineered components for hassle-free assembly and long-lasting performance․ Additionally‚ materials like PVC and recycled metal are eco-friendly options that can enhance durability․ Proper material selection ensures your carport remains sturdy and protects your vehicles effectively over time․ Always consider local weather conditions when deciding on the best materials for your structure․

Maintenance and Repair Tips

Regular maintenance ensures longevity․ Clean debris‚ inspect for rust‚ and tighten loose parts․ Addressing issues early prevents major repairs and keeps your carport safe and durable․

5․1 Regular Maintenance Requirements

Regular maintenance is crucial to ensure your carport remains durable and safe․ Start by inspecting the structure for any signs of wear‚ rust‚ or damage․ Clean debris from the roof to prevent water accumulation‚ which can lead to corrosion or structural weakness․ Check all bolts and screws for tightness and secure any loose components․ Apply anti-rust treatments to metal parts annually to protect against corrosion․ Additionally‚ repaint faded or chipped surfaces to maintain both appearance and protection․ Addressing these tasks regularly will extend the lifespan of your carport and prevent costly repairs down the line․

5․2 Addressing Common Issues

Common issues with carports include rust‚ loose components‚ and roof damage․ To address rust‚ sand affected areas and apply a rust-inhibiting coating․ For loose parts‚ tighten bolts and screws promptly․ If roof panels are damaged‚ replace them immediately to prevent leaks․ Check for alignment problems and adjust frames as needed․ Regularly inspect post anchors to ensure stability․ Additionally‚ trim overhanging branches to avoid debris accumulation․ Addressing these issues early can prevent more severe problems and maintain the structural integrity of your carport․ Always refer to your maintenance guide for specific solutions tailored to your carport model․

Troubleshooting Common Assembly Issues

Common issues include missing parts‚ misaligned frames‚ and unclear instructions․ Verify all components are included and consult the manual or contact support for clarification if needed․

6․1 Alignment and Leveling Problems

Alignment and leveling issues are common during carport assembly․ Ensure the foundation is even and use a spirit level to check the frame’s alignment․ If posts or beams are uneven‚ adjust them before securing․ Tighten all bolts firmly to maintain stability․ Verify that roof supports are evenly spaced and properly aligned with the frame․ If misalignment persists‚ consult the manual or contact support for guidance․ Proper alignment is crucial for structural integrity and safety․ Always double-check your work to avoid costly repairs or instability in the finished carport․

6․2 Tightening and Securing Components

Tightening and securing components is a critical step in carport assembly․ Use a wrench or impact driver to ensure all bolts and screws are tightened firmly․ Always follow the torque specifications provided in the manual to avoid over-tightening‚ which can damage the material․ Start by securing the base posts to the foundation‚ then move upward to the frame and roof supports․ Tighten bolts in a sequential order to maintain even pressure and prevent warping․ Double-check all connections to ensure they are snug and stable․ Properly secured components are essential for the structural integrity and long-term durability of your carport․

Safety Precautions

Always wear protective gear like gloves and safety glasses․ Ensure the structure is stable before working underneath it․ Follow the manual’s safety guidelines to avoid accidents․

7․1 General Safety Guidelines

Always wear protective gear‚ including gloves and safety glasses‚ to prevent injuries․ Ensure the build site is clear of obstacles and tripping hazards․ Check weather conditions and avoid assembly during strong winds or rain․ Keep children and pets away from the work area․ Read the manual thoroughly before starting and follow all instructions carefully․ Use proper lifting techniques to avoid strain․ Ensure all tools are in good condition and used correctly․ Never overload the structure during assembly‚ and double-check stability before proceeding․ Follow local building codes and regulations to ensure compliance and safety standards․

7․2 Handling Tools and Materials Safely

Always store tools and materials in a dry‚ secure location to prevent damage or loss․ Use tools only for their intended purposes and ensure they are in good working condition․ Inspect materials for defects before use and handle them carefully to avoid injury․ Lift heavy items with proper technique or seek assistance to prevent strain․ Keep the workspace clean and free from clutter to minimize tripping hazards․ Secure loose materials and ensure they are properly anchored during assembly․ Follow manufacturer guidelines for tool usage and material handling․ Properly dispose of packaging and waste to maintain a safe working environment․

When to Hire a Professional

Always inspect tools and materials for damage before use․ Use proper lifting techniques to avoid injury․ Store materials securely and keep the workspace tidy to prevent accidents․ Follow safety guidelines for tool operation and material handling to ensure a safe assembly process․ Dispose of packaging and waste responsibly․ Maintain a clean and organized workspace to minimize hazards․ Wear protective gear when handling sharp or heavy objects․ Ensure all tools are properly stored after use to prevent misuse or damage․ Adhere to manufacturer instructions for handling specific materials․ Keep children and pets away from the assembly area․ Regularly check tools for wear and tear․

8․1 Signs You Need Expert Help

If you lack DIY experience or time‚ hiring a professional is advisable․ Complex designs‚ large carports‚ or local building codes may require expert assistance․ Safety concerns or lack of tools should also prompt professional help․ If unsure about structural integrity or proper assembly techniques‚ consult a specialist․ Additionally‚ if the carport requires electrical work or advanced roofing‚ professional installation is recommended․ Experts ensure compliance with local regulations and provide warranties for their work․ Don’t hesitate to seek help if the project seems overwhelming or time-consuming․ Professionals can complete the job efficiently and ensure a durable‚ safe structure tailored to your needs․

8․2 Finding a Reliable Installer

To find a reliable installer‚ research local contractors with experience in carport installations․ Check online reviews‚ ask for referrals‚ and verify licenses and insurance․ Request quotes from multiple providers to compare prices and services․ Ensure the installer has a proven track record with similar projects․ Ask for a portfolio or references to assess their work quality․ Clearly discuss project timelines‚ payment terms‚ and warranties․ A professional installer will provide a detailed contract outlining all aspects of the job․ This ensures transparency and accountability‚ giving you peace of mind throughout the installation process․ A reliable installer will also offer post-installation support if issues arise․

Cost Considerations

Budgeting for carport assembly involves calculating material costs and labor fees․ DIY kits can save money‚ while professional installations ensure quality but increase expenses․ Compare quotes and consider long-term durability․

9․1 Budgeting for Materials

Budgeting for carport materials requires careful planning․ Metal carports are often more affordable upfront‚ with prices starting around $1‚000‚ while wooden carports can range from $2‚000 to $5‚000 or more‚ depending on size and quality․ Factors such as roof style‚ material thickness‚ and custom designs can significantly impact costs․ It’s essential to compare quotes from suppliers and consider long-term durability and maintenance expenses․ Additionally‚ check for any local building codes or permits that may add to the initial investment․ Allocating a contingency fund for unexpected expenses is also wise to avoid budget overruns during the project․

9․2 Labor Costs for Professional Installation

Labor costs for professional carport installation vary depending on size‚ material‚ and complexity․ On average‚ professional installers charge between $500 to $2‚000 for metal carports‚ while wooden carports may cost more due to additional labor requirements․ Larger or custom designs can increase labor fees significantly․ Some companies offer free installation with purchase‚ which can save money․ Always request detailed quotes from multiple contractors to compare prices and services․ Be sure to inquire about additional costs for site preparation or foundation work‚ as these may not be included in the base labor cost․ Budget accordingly to avoid unexpected expenses․

Comparing Carport Types

Metal carports are durable and low-maintenance‚ while wooden carports offer a traditional aesthetic․ Choose based on budget‚ durability‚ and style preferences to suit your needs best․

10․1 Metal vs․ Wooden Carports

Metal carports are known for their durability and low maintenance‚ making them a practical choice for long-term protection․ They are often more affordable and quicker to assemble than wooden carports․ Wooden carports‚ however‚ offer a timeless aesthetic and can blend seamlessly with traditional home designs․ Wood requires regular maintenance‚ such as painting and treating‚ to prevent rot and insect damage․ Metal carports are resistant to pests and weathering but may lack the charm of wood․ Consider budget‚ style preferences‚ and maintenance willingness when deciding between the two․ Both options provide reliable shelter‚ but the choice depends on your specific needs and preferences․

10․2 Attached vs․ Freestanding Carports

Attached carports are connected to a building‚ offering convenience and space efficiency‚ while freestanding carports can be placed anywhere on the property․ Attached carports often require additional structural support to ensure proper integration with the existing roofline‚ potentially increasing installation complexity․ Freestanding carports provide more flexibility in placement and can be easier to install‚ as they don’t require attachment to a structure․ Both options offer reliable protection for vehicles‚ but the choice depends on available space‚ desired design‚ and installation preferences․ Freestanding carports are ideal for larger properties‚ while attached carports are perfect for maximizing space in smaller yards․

Completing your carport assembly is rewarding‚ providing protection and enhancing your property․ Follow instructions carefully for a durable structure that meets your needs and ensures vehicle safety․

11․1 Summary of Key Assembly Steps

Successful carport assembly involves several key steps: preparing the site‚ laying a sturdy foundation‚ assembling the frame‚ installing roof support beams‚ and securing roofing panels․ Ensure all components are aligned and tightened properly․ Conduct final checks to verify stability and safety․ Always follow the provided instructions and consider seeking help if needed․ Regular maintenance‚ like inspecting for rust and tightening loose parts‚ will extend the carport’s lifespan․ By adhering to these steps‚ you can achieve a durable and functional structure that protects your vehicle and enhances your property․ Proper planning and execution are essential for a stress-free DIY experience․

11․2 Final Tips for a Successful Project

To ensure a successful carport assembly‚ plan thoroughly and adhere strictly to the instructions provided․ Use appropriate tools and safety gear to avoid accidents․ Patience is key—don’t rush‚ as precision ensures stability and durability․ Double-check all connections and alignments before finalizing․ Organize materials beforehand to streamline the process․ Follow manufacturer guidelines for materials and tools to avoid damage․ After assembly‚ inspect the structure for any gaps or weaknesses․ Regular maintenance‚ such as tightening bolts and cleaning debris‚ will extend the carport’s lifespan․ Celebrate your accomplishment and enjoy the protection and functionality your new carport provides!